Our Blog

What Is Particle Board Used for Furniture and Fixtures? Essential Basic Knowledge You Should Know

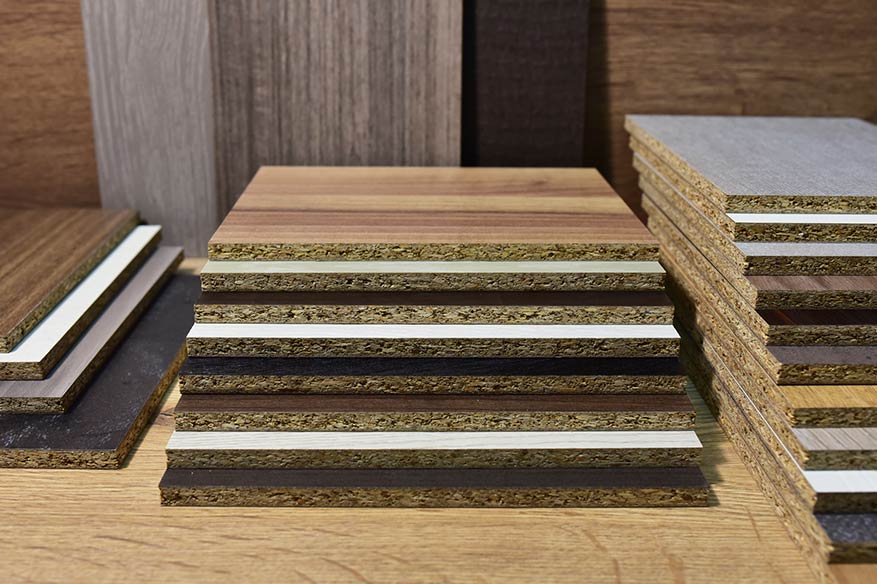

Particle board is widely used as a base material (core material) made from wood for furniture, building materials, and DIY supplies. There are various types of base materials, but along with plywood and MDF (Medium Density Fiberboard), one of the most well-known is “particle board.” Many wooden fixtures sold by Store Express also use particle board as their base material. However, some people may not be familiar with what exactly it is.

Here, we will introduce the types and characteristics of particle board.

Table of Contents

1. What is Particle Board?

Particle board is a type of wood-based board made by processing wood broken down into pieces of various sizes, bonded together with adhesive. It is also called chipboard or shaving board.

It is a material used in a wide range of applications, from building materials such as wall, floor, and roof substrates to furniture, fixtures, and packaging materials.

In addition, boards made from larger-sized chips are called OSB (Oriented Strand Board) and are used as interior finishing materials, among other applications.

2. Types of Particle Board

Particle board can be divided into three types depending on how it is made: “single-layer,” “multi-layer,” and “three-layer.” The differences between the types are as follows:

- Single-Layer

Particle board made using chips of the same size is called single-layer. Since the chip sizes are uniform, the board has high density and even strength.

- Multi-Layer

Particle board with multiple layers is called multi-layer. Fine chips are used for the board’s surface, while the chips become larger toward the inside.

The overall density is lower, which increases resistance to bending and makes processing easier. Another advantage is that the surface tends to have a smoother finish. Store Express’s “OSB Wooden Shelf” uses this multi-layer structure.

- Three-Layer

This type consists of three layers made from chips of different sizes. Fine chips are used for the surface and back layers, while coarser chips are used for the inner layer.

Similar to multi-layer boards, reducing the density increases resistance to bending while also reducing weight.

⇒ Explore our store fixtures by Store Express

3. Characteristics and Advantages of Particle Board

Although particle board is used for a wide variety of purposes, what specific characteristics does it have? Below are the advantages of using particle board:

- Eco-Friendly and Inexpensive

Chips used for particle board can be made from waste materials from construction sites or unused leftover wood. This means there is no need to cut down forests to obtain raw materials, and wood that would otherwise be discarded can be utilized, making it eco-friendly and inexpensive.

Another advantage is that particle board itself can be recycled. It is truly a material that takes environmental considerations into account.

- Uniform Material Quality

Since particle board is made by bonding wood chips together, the resulting material is uniform in quality. Compared to natural solid wood, it has less warping, cracking, or distortion and is easier to process.

Furthermore, by adjusting the amount of chips during manufacturing, the thickness and size can be freely determined. Boards of various sizes can be produced to suit different applications.

- Excellent Soundproofing and Thermal Insulation

Particle board also excels in soundproofing and thermal insulation. Taking advantage of these properties, it is widely used in building materials that require cold protection and even as material for speakers.

4. Disadvantages of Particle Board

While particle board has many advantages, it also has some disadvantages. It is important to be aware of these when using particle board:

- Weak Against Water and Humidity

Since particle board is made by bonding wood chips with adhesive, it is weak against water and humidity. Exposure to water can cause deterioration such as cracking and warping. Therefore, it is best to avoid using it in wet or highly humid environments.

- Weaker Strength Compared to Other Wood Materials

Because it is made from accumulated chips, it is weaker than solid wood or plywood, which are single-material resources. It is not suitable for structural elements like building columns where high strength is required.

In addition, it lacks wood grain, so cut surfaces tend to look rough, and it is difficult to achieve the natural texture unique to wood.

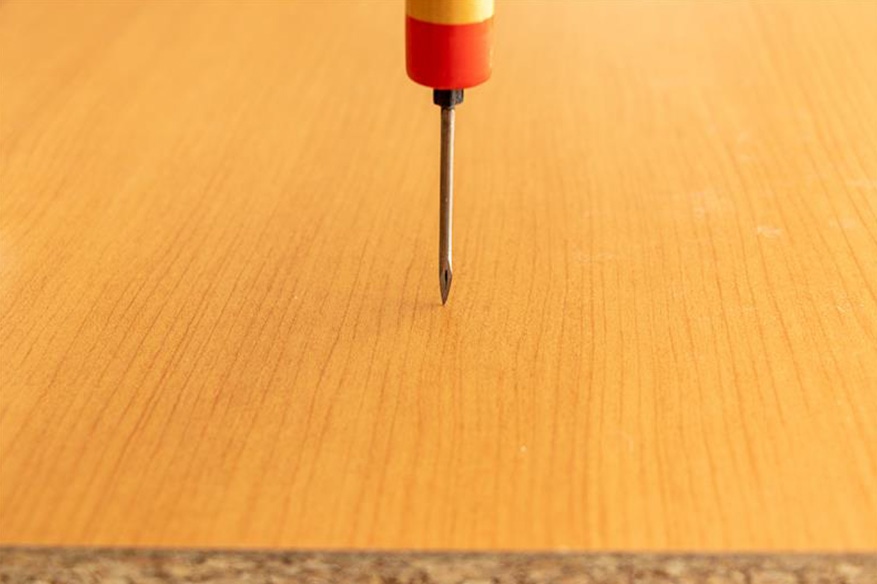

- Nails and Screws Do Not Hold Well

Although it is easy to process, particle board does not hold nails or screws well. While nails and screws can be used, there is a risk that they may come loose, so reinforcement with adhesive or other means is necessary.

- Prone to Sagging

If heavy objects are continuously placed on particle board, it may sag or warp over time.

5. Classification of Particle Board

Around the world, particle board is classified and evaluated not only by country-specific standards such as JIS (Japan), ANSI (USA), or EN (Europe), but also by common performance categories that help determine its best use. Major aspects include:

- Size and Thickness

Particle boards are manufactured in a wide range of thicknesses (typically 5–40 mm) and standard sheet sizes depending on regional practices. Furniture and building materials are often cut to standard panel formats such as 1,220 × 2,440 mm (4 × 8 ft).

- Surface Finish

Particle board can be used raw or processed with surface treatments. Typical categories include:- Raw Board (Unfinished): No surface treatment, sometimes sanded for a smoother texture.

- Veneered Board: Covered with thin natural wood veneers.

- Decorative Board: Laminated with melamine, resin sheets, or printed surfaces for aesthetic purposes.

- Structural Board: Designed for use in construction as a substrate.

- Strength and Mechanical Properties

Internationally, particle board strength is measured by bending strength, internal bond strength, and screw holding capacity. Higher grades are suitable for load-bearing furniture or building substrates, while lower grades are used for decorative purposes.

- Moisture Resistance

Boards are commonly available in:- Standard Grade (for dry indoor use, e.g., furniture)

- Moisture-Resistant Grade (for humid conditions, e.g., kitchens, bathrooms)

- High-Density or Exterior Grade (limited outdoor use, protected environments)

- Formaldehyde Emission

Many regions regulate formaldehyde emissions to reduce health risks such as “sick building syndrome.” Labels like E1/E0 (Europe), CARB Phase 2 (USA), or equivalent low-emission grades are widely recognized worldwide.

6. Let’s Use Particle Board Suitable for Its Intended Purpose

Particle board is an eco-friendly and inexpensive material that contributes to resource recycling. It also has many excellent features, such as a wide range of sizes and good workability. On the other hand, it has disadvantages such as being weak against moisture and prone to sagging under heavy loads.

The key to using particle board effectively is to understand its characteristics before using it.

Why not try utilizing furniture and fixtures made from particle board according to your needs?